First Look: KTM 2017 Four Strokes

With multiple upgrades and changes across all the four-stroke range, KTM have brought out a new generation of machinery for 2017.

In MY 2017 newly developed and constructed DOHC and SOHC engines with the latest electronic fuel injection provide not only the customary, high power levels expected from a genuine KTM enduro. With a compact architecture optimised down to minute details, these power houses also contribute significantly to the latest round of weight savings and further centralised masses, supporting the all-new chassis in delivering previously inconceivable levels of rideability.

Comprising four models that are all very different and yet united by KTM’s pursuit of quality, the EXC-F range of racing enduros is bound to suit a wide variety of riders with a preference for 4-stroke machines.

250 EXC-F

The smallest model of the KTM 4-stroke range provides a newly developed, strong engine and agile, flickable handling, making it a great choice for professional riders as well as ambitious amateurs. With an even more compact and powerful engine, as well as significant weight savings, the lively, small capacity 4-stroke once again extends its lead over the competition in MY 2017.

Its foundation shares many components with the successful 350 EXC-F engine and enjoys class leading performance with plenty of torque thanks to its advanced fuel injection system. The bike is easy to ride, agile and highly controllable for complete rider confidence, with state of the art technology for a great throttle response and finely controlled power delivery. The DDS clutch system with Brembo hydraulics offers a flawless clutch operation while the electric starter guarantees trouble-free starting in any situation.

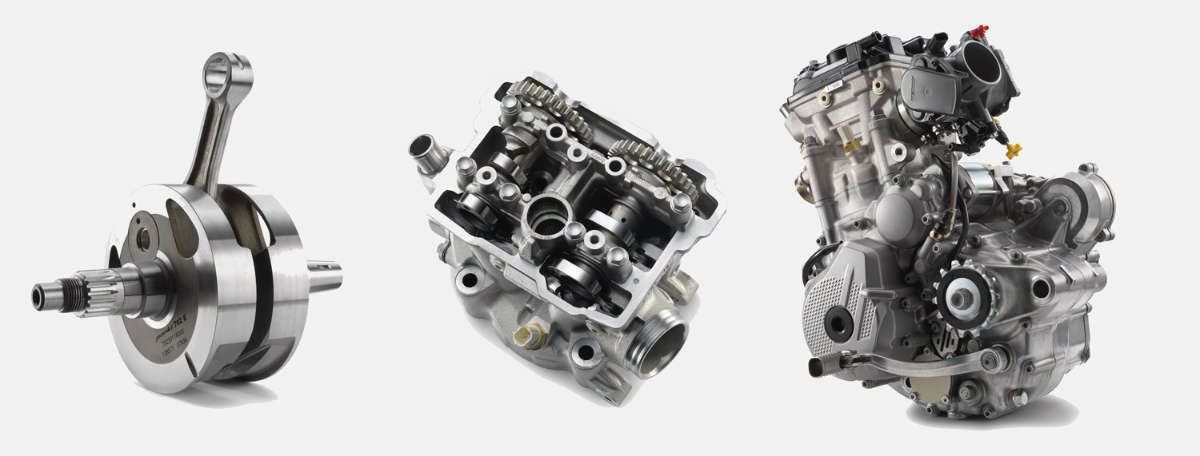

Engine

The new 250 EXC-F DOHC engine has been redesigned for even more compactness and further weight improvements, while delivering class-leading torque and power figures across the entire power band. A new architecture with an optimised shaft configuration makes the engine 20 mm shorter, contributing to the bike’s mass centralisation and effortless rideability. Another major benefit is a 1.5 kg weight reduction down to less than 27.6 kg, including an electric starter. At the same time, usable power is available all the way up to 12,800 rpm. With its new layout this engine meets the future Euro IV homologation limits.

The 250 EXC-F’s crankshaft utilises a 6 mm shorter connecting rod, which makes for an overall compact and lightweight engine with a snappy power delivery. A plain big-end bearing with two force-fitted bearing shells runs directly on the crank pin. This design is a major prerequisite for the extremely high engine speeds and the unrivalled maximum power of this 250 cm3 engine. Furthermore, it increases the engine’s durability, allowing extended crankshaft service intervals.

The centrepiece of the compact DOHC 250 is its cutting-edge cylinder head. Its twin overhead camshafts shed another 150 g for MY 2017, with friction-optimised finger followers boasting a 30% harder DLC coating and it features a revised valve drive. Four light-weight titanium valves and high-flow ports maximise the flow rate for an optimal power delivery and outstanding performance across a seemingly endless rev range reaching up to 12,800 rpm. New lateral brackets for two head stays make for an efficient engine mount within the frame, while reducing the transmission of vibrations.

The completely new design of the die-cast engine case allows for a much more centralised shaft configuration, moving the crankshaft closer to the bike’s centre of gravity, while the clutch shaft position has moved 11.1 mm to the rear and 26.9 mm up. This shortens the engine by another 2 cm, contributing to the handling benefits of increased mass centralisation. Newly designed engine covers feature an advanced surface structure in order to reduce the wear caused by the rider’s boots.

350 EXC-F

The 350 EXC-F is the ultimate enduro machine when optimum rideability and maximum enduro performance are called for. Thanks to its compact, powerful DOHC (double overhead camshaft) engine, low weight and perfectly tuned suspension, this machine masters each and every challenging type of terrain with ease. With its playful handling, the 350 EXC-F always holds the advantage when the going gets really tough. The longer the distance, the more riders on all levels benefit from this and the maximum fun factor is guaranteed.

The 350 4-stroke engine with a state-of-the-art electronic fuel injection system offers a very wide power band and is distinguished by a dynamic but low-fatigue power delivery – strong enough to beat any 450 in the E2 class.

Engine

For MY 2017, the 350 has once again been re-designed in order to make it yet more compact and lighter while delivering increased torque and power across the entire rev range. The new architecture with an optimised shaft configuration makes the engine 20 mm shorter for added mass centralisation and once more increased rideability. A major benefit of the new design is the weight reduction by 1.9 kg, down to a 28.5 kg – including an electric starter. It also now conforms to the future Euro IV standards.

Essential for the outstanding performance of the compact DOHC engine, the cylinder head demonstrates cutting-edge technology. Two overhead camshafts activate friction-optimised finger followers, now with a 30% harder DLC coating. Their revised timing is optimised for impressive low-end torque. Four lightweight titanium valves with new valve springs and retainers and high-flow ports maximise the flow rate for a wide powerband and outstanding performance across a seemingly endless rev range extending up to 12,000 rpm. Two new lateral brackets serve as an efficient engine mount via head stays, which at the same time minimise vibrations.

The completely new design of the die-cast engine case allows for a much more centralised shaft configuration, moving the crankshaft closer to the bike’s centre of gravity, while the clutch shaft position has moved 11.1 mm to the rear and 26.9 mm up. This shortens the engine by another 2 cm, contributing to the handling benefits of increased mass centralisation. Newly designed engine covers feature an advanced surface structure in order to reduce the wear caused by the rider’s boots.

The 350 EXC-F’s crankshaft features a stiffer design and employs a 6 mm shorter connecting rod, contributing to the compact and lightweight engine layout as well as the responsive power delivery. A plain big-end bearing with two force-fitted bearing shells runs directly on the crank pin.

450 EXC-F

The KTM 450 EXC-F is the strongest, most competitive bike in the E2 class. With its all-new, much more compact SOHC engine fitted in a re-designed chassis, which is lighter than ever, the 2017 model is all set to re-define the benchmark in its class.

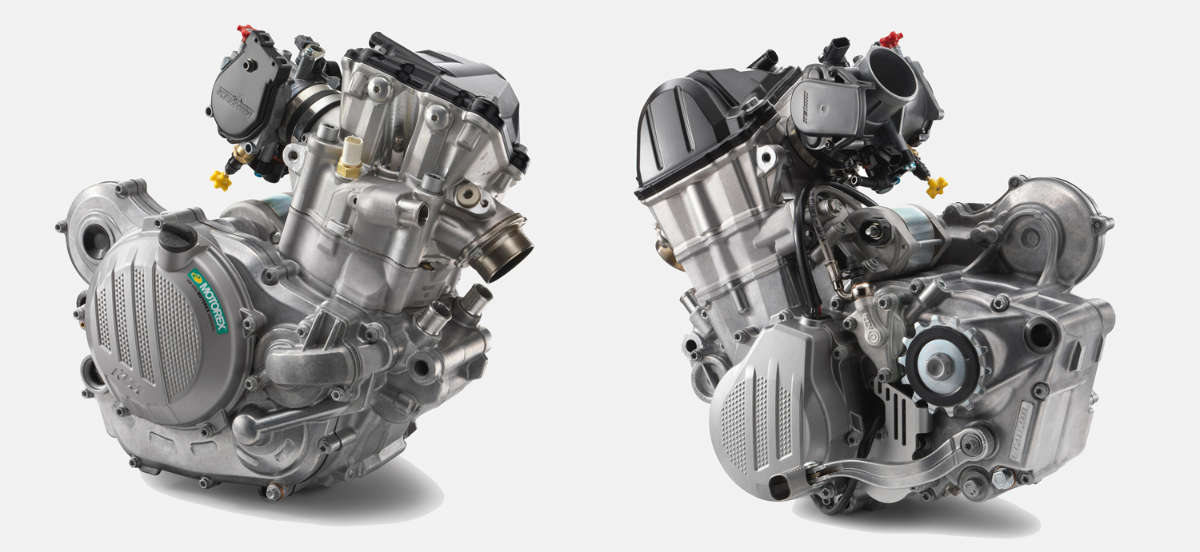

Engine

The 450 EXC-F’s fuel-injected SOHC powerhouse has been redesigned with the aim of making it the most compact and lightest 450 on the market, while delivering groundbreaking torque and power figures over the entire rev range thanks to a re-designed single overhead camshaft cylinder head and the latest electronic fuel injection. At the same time, an Euro IV homologation makes clear the environmental performance is also on par.

The SOHC cylinder head has been completely revised. An all-new overhead camshaft now controls the gas flow through optimised ports, while a re-designed water jacket and combustion chamber take care of combustion and heat management. The engine’s four valves now rely on extremely rigid rocker arms. The timing chain has been shortened and fitted with reduced-friction chain guides. New lateral brackets form efficient, low-vibration frame mounts via two head stays.

The new design of the die-cast engine case allows a much more centralised shaft configuration. By raising the crankshaft by 7 mm and backing it up by 9 mm moves it closer to the bike’s centre of gravity. It also shaves off another 550 grams of weight. Newly designed engine covers feature an advanced, highly wear-resistant surface structure.

The new 450 EXC-F’s crankshaft features a stiffer design and employs a shorter connecting rod, which makes for an overall compact and lightweight engine with a snappier power delivery than ever. It provides the same inertia as the predecessor, while a higher balancing factor reduces the vibration level. A plain big-end bearing with two force-fitted bearing shells runs directly on the crank pin. The oil feed required by this type of bearing is ensured by the engine’s pressure lubrication.

This design enhances the engine’s durability, allowing long crankshaft service intervals – a clear benefit with respect to maintenance time, effort and cost. An improved sealing concept with metal shims instead of seal rings reduces dead space within the crankcase and keeps the engine ultra-slim. A shorter primary ratio (31/76 instead of 32/76) reduces the shaft distance, contributing to the engine’s compact dimensions.

500 EXC-F

In MY 2017, the 510 cm3 single makes for a more dynamic enduro experience than ever, thanks to notable weight savings for a higher-than-ever power to weight ratio. At the same time, the enhanced mass centralisation and geometry delivered by an even more compact engine layout, among others, makes for an increase in rideability, which is absolutely essential to convert the power into a true racing benefit.

Engine

The 500 EXC-F’s fuel-injected powerhouse has been redesigned in order to make it the most compact and lightest 500 on the market, while delivering awesome torque and power figures across the entire rev range thanks to a reworked single overhead camshaft cylinder head and the latest-generation electronic fuel injection. At the same time, its Euro IV homologation demonstrates advanced environmental consideration.

The SOHC cylinder head has been completely re-designed. An all-new overhead camshaft now controls the gas flow through optimised ports, while a newly designed water jacket and combustion chamber take care of combustion and heat management. The engine’s four valves are now controlled by extremely rigid rocker arms. A shorter timing chain is fitted with reduced-friction chain guides. New lateral brackets securely fixate the engine to the frame via two head stays while reducing vibrations.

The stiffened new crankshaft of the 500 EXC-F employs a shorter connecting rod for an even more compact engine layout and reduced weight. Even though it retains the same weight, it provides five per cent more inertia than last year’s model while a higher balancing factor serves to further reduce vibrations. A plain big-end bearing with two force-fitted bearing shells runs directly on the crank pin. The necessary oil feed for this bearing is ensured by the engine’s pressure lubrication. This design enhances the engine’s durability, allowing long crankshaft service intervals for a further increase in maintenance efficiency. An improved sealing concept with metal shims instead of seal rings reduces space inside the crankcase, keeping the engine ultra-slim. Distance between shafts is reduced by employing a shorter primary drive ratio (31/76 instead of 32/76) for an even more compact design.

Across All 4 Strokes

Clutch

The 2017 four strokes employ the KTM-developed DDS clutch (damped diaphragm steel) with a wear-free steel basket and extremely heat resistant clutch plates. This clever design employs a diaphragm spring instead of the usual coil springs, which makes for a considerably easier clutch action. A diaphragm spring also leaves sufficient space for a damping system to be integrated into the clutch hub for increased traction along with enhanced durability. On top of that, it is fitted with a lighter basket, a re-designed inner hub and a pressure plate that provides a better oil supply and unsurpassed cooling. Actuated by Brembo hydraulics, the clutch ensures an easy operation and consistently precise control.

Engine Management System

The state-of-the-art Keihin Engine Management System with electronic fuel injection features an all-new 42 mm throttle body. Thanks to its unique injector position, the big 450 is hallmarked by a more direct response than ever before. Separate systems automatically take care of cold starts and idle adjustment. An optional map switch allows to select a different power curve in mid-race and to activate the unique traction control system for maximised grip.

Transmission

The new four strokes use a 6-speed enduro gearbox with gear ratios specifically optimised to their individual power delivery. An advanced KTM ‘No Dirt’ gear lever design prevents dirt from blocking the joint of the lever, contributing to a secure gear engagement. All KTM 4-stroke enduros of MY 2017 feature a gear sensor to sync up the engine’s power curve to the currently selected gear as well as the surface conditions.

Electric Starter

The 2017 four strokes receive as standard an electric starter. Engaging through a weight-reduced new starter drive, the strong starter motor made by Mitsuba is powered by a reliable lithium ion battery. For maximum weight savings, the kick-starter has been deleted, but riders who insist on a purely mechanical back-up can easily retrofit a kick starter replacement kit from the PowerParts range.

Frame

The high-tech, lightweight chrome-moly steel frame is the base of the EXC series’ handling, rideability, precise cornering and excellent stability. Due to wider but lower profiles for the steering triangle combined with hydro-formed side tubes, the torsional rigidity was raised by 20% providing more cornering and track stability.

At the same time the longitudinal stiffness could be reduced by 30%, which results in better absorption of the impact energy from the suspension, in short: more comfort and less rider fatigue. Laterally attached, lightweight engine head stays contribute to a reduced vibration level. Two threaded inserts in the lower cradle tubes make a rugged mount for an optional skid plate. In MY 2017, the EXC frame is 300g lighter than the predecessor and a full kilogram lighter than that of the lightest competitor.

Subframe

The brand new subframe, manufactured from a new type of strong aluminium sections, tips the scales at less than 900g – 20% weight savings over the previous generation.

Swingarm

An updated swingarm design allows for an optimised mounting position of the PDS (progressive damping system) rear shock for increased progression. Furthermore, the new cast aluminium. MY 2017 design achieves another weight reduction of 220g, combined with perfect flex behaviour.

WP Split Forks

The all-new WP XPlor 48 upside-down fork is a split fork developed by WP in close collaboration with KTM. While it has springs on both sides, the damping action is split between the fork legs: compression on the left side, rebound on the right. The forks are easily adjusted for compression and rebound by twisting the individual dials on top of the fork tubes (30 clicks each). In addition, a longer and sealed hydro-stop guarantees better resistance against bottoming-out.

Due to high-quality materials and a state-of-the-art production process, the new XPlor 48 forks with some 300 mm of travel combine outstanding response and damping characteristics with weight savings of around 200g over the previous generation of forks. In addition, a new, optional preload adjuster allows to quickly dial up one of three different spring preload settings without any tools.

New PDS Shock

The newly developed WP XPlor rear shock retains the signature KTM PDS design where the shock absorber is directly connected to the upper side of the swingarm without a linkage system. This set-up has now been re-designed with the new frame and swingarm architecture in mind. It boasts the best possible mounting geometry, provides even more progressive damping, and features an all-new shock absorber body with a smaller piston and a larger reservoir.

KTM has reduced the piston diameter from 50 to 46 mm, with the total length reduced by 2.5 mm and the shock stroke by 4 mm, for total weight savings of more than 600g. In addition, it is now mounted 5 mm closer to the centre line, resulting in nearly symmetrical loads on swingarm and frame, as well as more space for the exhaust.

A second piston works together with a closed cup (instead of a needle) towards the end of the stroke and is supported by a progressive shock spring for enhanced protection against bottoming-out.

New Rear Brake Caliper

The rear brake pedal length has been extended by 10 mm while the diameter of the rear brake caliper piston has been reduced from 26 to 24 mm.

Misc

Other details include, KTM’s ‘No Dirt’ footpegs - 6 mm higher than the SX versions - stiffer radiators, 8.5L fuel tank, new seat design, new air box design, 2017 graphics, Neken handlebars, speedometer.

Technical Data