Pro bike: Wil Ruprecht’s TM Boano Racing EN 300 Fi

Enduro21 takes a closer look at the TM EN 300 Fi four-stroke the Australian Wil Ruprecht and the TM Boano Factory racing team are using to inject fresh life into the 2021 EnduroGP World Championship.

When Boano Racing took over as the official TM Racing team in the off-season it was a big move but it is proving a very successful one. Blue TM bikes are all over the different GP class podiums and Wil Ruprecht is upsetting the World Championship apple cart with timesheet-topping performances and a maiden GP day win ahead of Brad Freeman and Steve Holcombe.

The fastest of the new swarm of blue bikes in the GP paddock is this EN 300 Fi 4T, Wil’s race-winning machine. Racing in the highly competitive E2 class, this 300cc four-stroke is on the money in terms of current fastest bikes out there in the hands of Ruprecht.

Enduro21 caught up with the team and Wil’s chief mechanic Roberto “Tino” Marocco to find out more about the blue rocketship…

All TM parts are TM factory parts

TM’s historical bread and butter as a business is their engine production with kart engines as much a part of their history as the bikes. You’ll also find them winning Supermoto World Championships plus competing in the Moto 3 class at MotoGP.

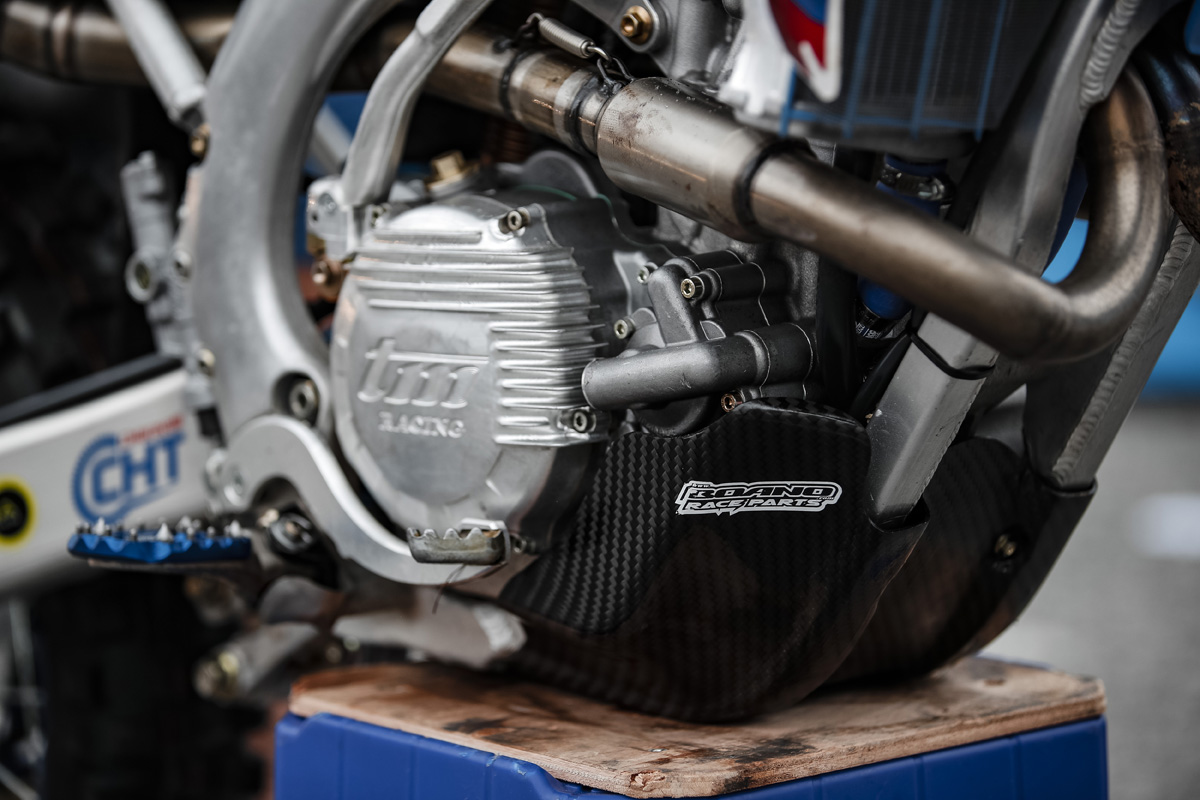

The reality is all TMs are hand built and therefore in terms of how factory or special this four-stroke engine is, “we do nothing really, the bikes are already good”.

Inside this 300cc, 4T, fuel injected engine the only difference is a machined head to perfect the combustion and help with deliver smooth and strong power delivery through the rev-range.

There’s also a slightly different weight on the flywheel to “increase the inertia” and give different engine reaction, particularly entering corners explains Tino.

Longer exhaust header pipes, those distinctive twin set exiting the cylinder under the standard radiators and snaking back around under the seat are also making a difference on Wil’s bike.

The additional length to standard adjusts the low-down power characteristic to make a flatter and smoother spread of power for the rider to access. The silencer is the standard part and unbranded.

TM are a small manufacturer and do a lot of work in-house, that includes the electronics. Again, it is all sstandard but here’s where TM being a smaller manufacturer is a benefit. The bike development of parts like the ECU has a direct link from the race bikes like this to the production bikes. So what these guys develop and perfect on the tests makes its way onto the bikes you can buy.

One thing hidden is the “simplified” electrical system and wiring loom – it’s paired down to just what they need and now more which is a common mod for race teams over the standard bike.

Sexy black top

The configuration for the airbox and fuel tank on the TM four-stroke is reverse to convention, i.e., the air box sits up top behind the head stock and the tank is under the seat. The airbox is standard Tino tells us but the cover is an eye-catcher of a part specially made from carbon fibre by the Boano team to be stronger (and look sweet too).

The engines are also blinged up by the saucy engine covers on the ignition and clutch side which are an in-house machined part from TM on all models.

Chiaravalli sprockets

TM Boano Racing team use Chiaravalli sprockets and Regina chains. The rear sprocket is the model with the tougher steel outer and Wil runs 13-50 final gear ratios. One neat part the team adds is the protector inside the sprocket to spare the spokes if the chain comes off.

Underneath the swingarm, the chain guide and sprocket protector is yet another Boano Racing part.

Home-grown

TM have always manufacturered some of their own parts, often those which they cannot source economically in the quantities they need from a supplier.

The team, Boano, are also well established in developing their own parts for off-road and it seems fitting the two should come together and collaborate not just for the race team but in bike development for the TM range now.

Suspension & chassis

TM bikes are unusual in the grand scheme of things for many reasons but one is the aluminium twin spar frame – another home-grown component – which stands apart from the many steel backbone chassis’ from so many other enduro bike manufacturers. It’s more like a Japanese main frame than a European one to look at.

TM bikes are known for their higher spec parts straight out the box too. One such is the KYB front suspension which is standard here except for different (heavier) springs to suit Wil and his harder settings.

The triple clamps are standard billet aluminium parts machined in-house at the TM factory and Ruprecht does not run any changes to off-set either.

Boano fit their own fork gators (just visible behind the front fork guards). The reason is to keep the dirt and but especially moisture out as the seals as the bikes stand outside overnight at the EnduroGP round parc fermes.

The rear suspension is also “a little harder” with a stiffer spring to suit Wil’s weight and riding style. The shock itself is a TM unit – yes, they make that themselves too.

Going taller

Up top where Ruprecht does his day job are a set of number six model Magura handlebars which are taller than stock. It is unusual in a race paddock of this calibre to find a rider who fits taller bars, normally it goes the other way.

Wil also changes his seat to be a little higher too. TM have different options for seat height if you’re buying a bike and Wil has gone for a little more height “to help through those times when you’re legging through rocks” Tino tells us.

Other controls which are non-standard include the Boano Racing footpegs which sit in standard position, but are wider than the stock part.

The Brembo clutch master cylinder is also a little different and lighter to use than the standard clutch (11mm versus 10mm standard). Circuit handguards are fitted to all TM and the team use the same.

Mixing things up

Perhaps the area of this Pro Bike which is the most ‘pick and mix’ are the braking components. Galfer discs, Brembo front calipers, Nissin rear caliper… it feels unusual to see such a mixture on an official manufacturer’s race bike.

The sexy-looking front Galfer disc is actually the same size as stock with Galfer pads biting it inside a Brembo front caliper and master cylinder. These are the standard Brembo parts common on other production bikes in the market to and not an expensive factory upgrade like you might find on other factory bikes – it is proof that the right kit works and you don’t always need the expensive stuff.

At the rear they run a solid Galfer disc which is not as hefty as some rear stoppers that you’ll see in the EnduroGP paddock where some riders use way more back brake and feel the need for a solid piece of steel back there. There are no disc guards front or rear either you’ll notice but the rear Galfer rotor is a robust five millimetres thicker than standard.

Together with the Nissin rear caliper, overall the braking system proves the point that TM as a manufacturer, and Boano are a race team, adopt a less conventional approach to parts on the bikes and go for what works best for them.

Maxxis tyres and mousses on Excel stock rims

Tyre set-up is always an intriguing one at the highest level of enduro. Usually that means different combinations of harder or softer tyres versus harder or softer mousses.

Tino tells us that Ruprecht is a little different to some in the team in going for a softer Maxxis tyre with a harder mousse rather than the other way. The tyres and mousses sit on the standard Excel rims.

Generally, the EN 300 four-stroke is a beauty to look at and makes fascinating viewing. They are unique-looking bikes and the new team run by Jarno Boano’s very experienced squad feels like step forward for the Italian manufacturer.

If results are a measure of anything in this world, things seem to be going the right way for both TM and Ruprecht in 2021.

Photo Credit: Enduro21 | Andrea Belluschi