Pro Bike: Billy Bolt’s 2020 SuperEnduro Husqvarna FE 350

Enduro21 takes a closer look at Billy Bolt’s 2020 SuperEnduro World Championship winning Husqvarna FE 350.

Little did we know when we caught up with the Rockstar Energy Husqvarna Factory Racing at the penultimate SuperEnduro round in Budapest, Hungary that we were witnessing the final race of the 2020 World Championship.

Events sure took a turn following that trip and since the final round was cancelled, effectively it meant that we were looking at the championship winning machine right there and then.

This is the Husqvarna FE 350 Billy Bolt took to three of the four 2020 SuperEnduro victories. Apart from a glitch (by his own admission) in Germany, Billy’s form from the opening moto was something else and so it proved as he had the measure of the very best of the rest this season.

>>> Pro Bike: Taddy Blazusiak’s 2020 SuperEnduro KTM 350 EXC-F

To get the low-down on Billy’s bike, we spoke to his right-hand spanner man Lee Edmondson, who talked us through the details and some of the special aspects on this factory bike.

Like all the factory machines raced at the highest level indoors in SuperEnduro, the base machine is Husqvarna’s FE enduro model but with a healthy dose of motocross bike thrown at it…

Mix n’ match motors

Billy’s indoor bike is an FE 350 with the frame straight from the stock bike and the WP Suspension also ‘off the shelf’ though obviously fitted with Cone Valve forks and X-ACT Pro shock absorber. What’s different is the Husqvarna factory-built motocross engine and five-speed gearbox.

“The motocross engine is a bit more responsive,” explains Billy’s trusted mechanic Lee Edmondson. “Obviously the five-speed gearbox means the ratios are closer together but we still run the enduro flywheel, stator and the electrics.

“We run those parts from the enduro bike to avoid stalling – if you ran an MX bike on the tight SuperEnduro tracks it would be a problem. But we want the motor to be aggressive and overall it is built more towards a motocross bike than an enduro.

Factory race teams often play with the standard clutch bore size at the lever – the master cylinder – but Billy’s FE 350 is different.

“It’s something the factory works on,” continues Lee. “We test different engines in different tracks and we just swap between the engines when we’re testing, we’re not allowed to go into them, they come straight from the factory.

“When we test we’ll have a low-end power option, a high-end power engine, that kind of thing. Billy uses the high compression engine, which is a bit comfier and has more power, Billy is a big lad, so the extra power comes handy for him!

“The airbox and everything inside the intake is stock but on the outside the exhausts system is an FMF Factory part sent to suit the indoor set-up. FMF have been working with the team for a good few years now, with Colton Haaker before Billy, so they have great exhaust to suit indoors.”

Five-speed gearbox but who needs gears?

The motocross engine brings with it a five, not six, speed gearbox.

Pre-season testing included sorting the optimal gearing for the tight indoor tracks. “The gearing on the bike is 12-50, obviously with the tougher Supersprox sprockets (gearing is 13-52 on the standard FE 350)," Edmondson explains.

We did a lot of testing with the 12-49 gearing but when we came to the first round we changed to 12-50 in first practice and have stuck with that ever since.”

Like all the factory machines raced at the highest level indoors in SuperEnduro, the base machine is Husqvarna’s FE enduro model but with a healthy dose of motocross bike thrown at it.

“Having said that, at most of the tracks this year Billy hasn’t been out of second gear. In fact, in Poland he hit the gear lever in final qualifying just before Superpole and he rode it back to the pits, I worked on the bike, put it in neutral oiled the chain and found he’d bent the selector shaft.

“It was too close to Superpole to change it so I put the bike in second gear just to rode off and couldn’t change gears. The first race followed on pretty quickly, so it was stuck in second gear for that too – I just took the gear lever off and he did the whole thing in one gear and no gear lever. That track suited it luckily, but it just shows you.”

Personal touches a plenty

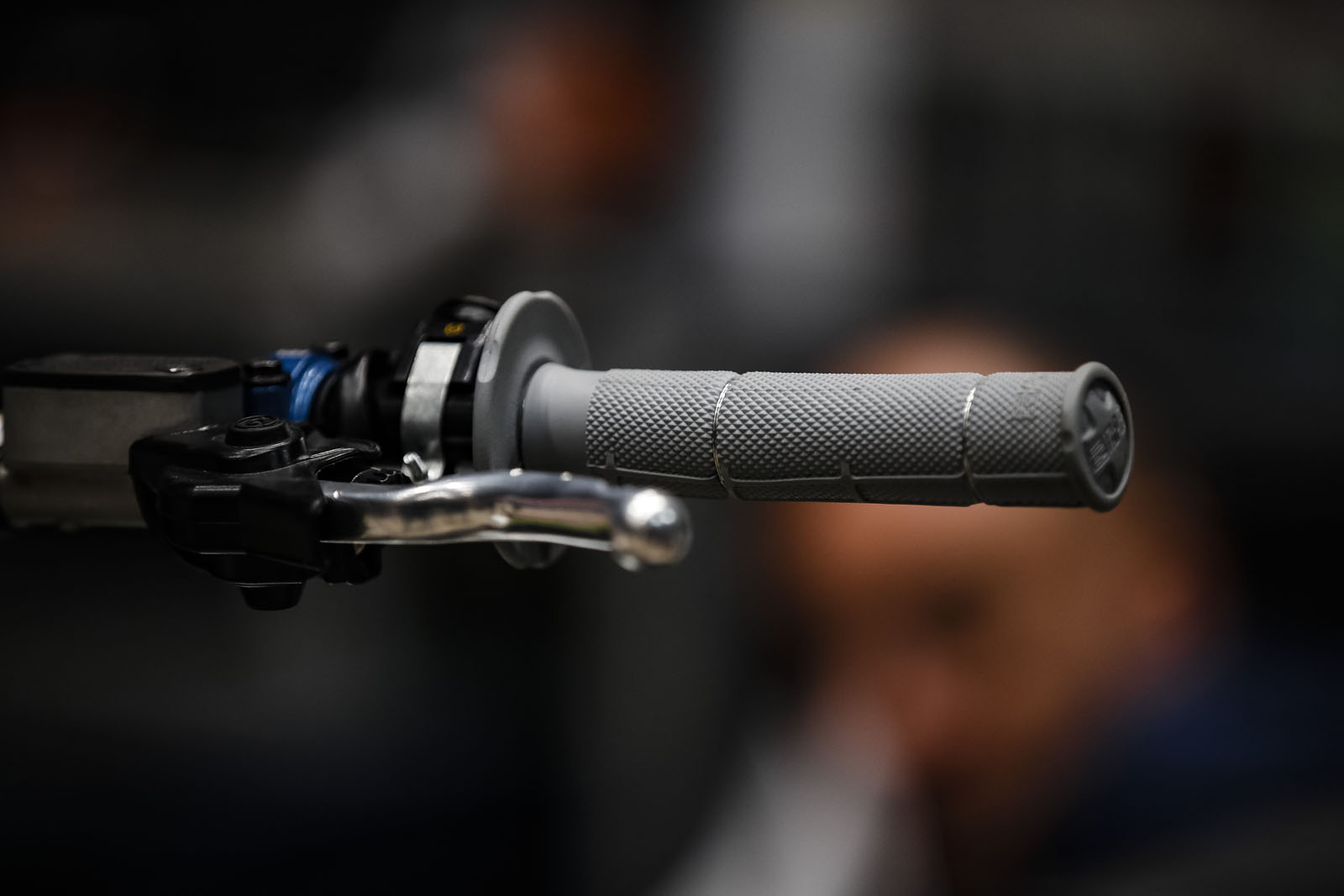

Billy likes a higher seat, “we have an extra 20mm in this one.” Says Edmondson. “One thing he likes is a longer, stretched grip on the left side.

The grip is standard, but I have to stretch it – I think it is just to match the feeling from a trials bike (Billy competed at British and World Junior level trials before switching to enduro).

“The Pro Taper grip glue is so good I just put a bit of in the end of the grip, slide it on to a mark on the bars, stretch it and let it settle.

“When I first started working with Billy it was strange and took a little bit of practice to get right, but I do it pretty quick now. The grip is 140mm long, so it’s quite a bit longer.

“He also gets a spanner out and bends his clutch leaver up a bit, he does this himself. He has little bits like this, it’s what he’s used to so we don’t argue about it, I just let him crack on with it.”

Those little bits include the skateboard grip tape for his legs to get a better hold on the bike which we focused on in our “Spotted” feature last month.

Billy runs the 5mm lower and 5mm further back Raptor Titanium footpegs. “On some occasions we might run 10mm lower and 10mm further back footpegs,” adds Lee.

Mixing enduro and motocross clutch parts

Factory race teams often play with the standard clutch bore size at the lever – the master cylinder – but Billy’s FE 350 is different.

“The clutch has the standard 10mm bore master cylinder, I think the two strokes come with a nine millimetre bore at the lever. Maybe it’s surprising he sticks with standard parts because not many riders do.

“None of the parts on the bike are really special. This year we have swapped to use the Husqvarna Accessories more on the factory bikes – like the 22mm off-set triple clamps and the powerful Brembo brake caliper for example, which are available through any Husqvarna dealer.”

It’s not all stock though as Lee explains. “When we were testing the clutch was getting hot sometimes, fading a little at times, so we changed the outer spring for a heavier one, which is standard on the motocross bikes.

It’s not a special part, it just comes from the motocross bikes. The team also run the Rekluese cover, which is harder and has more oil capacity”

Importance of testing pre-season

Edmondson mentions the pre-season testing several times while we run around the bike and it becomes clear one difference for Bolt this season was arriving with a bike set-up and ready.

In the pre-season Billy and Lee went to a test track near Girona, Spain for two weeks to test suspension with WP and basically get the bike dialled in.

It was key to arriving at the start of the 2020 season fully prepared with the bike (and rider) ready.

They also run a second security bolt in the rear wheel too, which Lee explains is better when running a soft or smaller mousse.

“Two years ago, we literally started testing the first ever day he rode a SuperEnduro track and we kind of went round in a big circle because he didn’t know what to expect.

Also, back then he was getting faster through the season and getting to know what he was doing so the bike was changing.

“This season he is riding well, knows what he wants, and we had the bike set up pretty good. We did a lot of testing in Spain and Billy has also been riding his practice bike a lot, which is pretty much the same as the race bike. We had the set-up pretty dialled before the season.

In some ways the testing never stops – he’ll try something on the practice bike and if it works he’ll tell me and I’ll put it in the race bike.”

Michelin mousse options

“We run Michelin tyres with the supersoft tyre in the back always and in the front we change between the big one (100) or the 90/90 front depending on the race,” explains Lee, talking about tyre choices. But it is the mousse options which they play with more often.

“Nine out of 10 times we go with a ‘used’ 140 Michelin mousse in the back and sometimes, like in Germany where it was quite slippery, we go for the 120 mousse.

We do drill the mousses sometimes so they’re a little bit softer still.”

They also run a second security bolt in the rear wheel too, which Lee explains is better when running a soft or smaller mousse.

A third security bolt is added for outdoor competition when the two-stroke bike is used in WESS events “just to keep a strong grip on the rear in conditions like Romaniacs or Erzberg.”

Details that matter

Further details around the factory Husqvarna include the two start buttons, like all factory Husqvarna and KTM teams use in enduro, motocross and supercross, both indoors and out these days. One on the bars and another on the frame, under the seat.

A CNC machined aluminium throttle housing is basically stronger, and as described on our recent look at Taddy Blazusiak’s SuperEnduro EXC-F 350 KTM is almost unbreakable.

Pro Taper handlebars are close to a common 999 bend (Renthal) which is widely used across many pro riders. The Excel rims front and rear are stronger, distinguished by the yellow writing.

Protection is mixed across the bike with a saucy carbon fibre P3 skid plate, with linkage protector.

Billy runs the 5mm lower and 5mm further back Raptor Titanium footpegs. “On some occasions we might run 10mm lower and 10mm further back footpegs,” adds Lee.

The TM Designworks chain guide and rear sprocket guard also has the extra metal protector up top, basically blanking out the gaps between the mount points.

Brake disc/rotor protection is as found across the factory Husqvarna enduro team with Acerbis fully enclosing the front and a solid ZipTy guard mounted on the rear brake calliper out back.

The rear brake lever has a titanium tip and also they use the two-stroke enduro model lever, which sits closer to the engine and out of the way more from rocks.

Another motocross model part is the clear (6.5 litre) fuel tank which runs, “no more than four litres – I’ve got a mark I fill it up to and no more.”

There are no lights on the factory bikes these days, just a sticker inside the headlight lens. “It’s just the motocross wiring loom under there too because we really don’t need all the enduro lights and wiring, it’s just something else to smash,” Lee concludes.

Indeed, Billy did smash it in 2020.

Photo Credit: Enduro21/Andrea Belluschi