Pro Bike: Steve Holcombe’s Beta RR Racing 350 4T

We begin the first in a series of 2020 Enduro World Championship winning ‘Pro Bike’ features with the machine at the very top of the tree, Steve Holcombe’s Beta RR Racing 350, a weapon which brought the British rider the overall EnduroGP crown, his first E2 world title and Beta their first-ever four-stroke honour.

Halfway through 2019, Enduro21 caught up with Steve Holcombe at Beta’s press introduction and model launch in Italy. At the time he explained a switch to four-stroke for the 2020 season was on the cards and was just beginning the process of sorting out exactly which of Beta’s four, 4T models to race. The 350, 390, 430 and 480cc models were all an option but the end he settled on the 350 and a jump into the E2 class.

Whichever he’d chosen it was always going to be a step into the unknown for a rider who’d taken all his world titles aboard a 300 two-stroke until that point. It was also a step for Beta who had equally only previously won their many world titles with two-stroke models.

Enduro21 takes a closer look at the details behind the 2020 world champion’s bike, his set-up secrets, changes over standard and just how factory is this Beta RR 350?

Engine evolution

One fact you couldn’t deny before 2020 was the unproven Beta 4T engines. It’s not that the Italian manufacturer hadn’t properly tested the engines or even that the bikes are particularly new, but in World Championship racing Beta certainly hasn’t been here before and Holcombe took a minor step of faith. In the end the 4T proved 100% reliable all season and come the final race and final test, proved the least thirsty option also.

What’s going on inside this hand-built 349.1cc, DOHC, titanium valved four-stroke engine? Things are basically standard but “tweaked” is the short answer.

Internally the airbox and throttle body are standard but the piston has a bit more compression (standard is 13.19:1) and the cylinder itself is “cleaned out a bit” in the intake port by the factory engine builder.

“We have worked on the CDI,” explains Beta’s Enduro Team Manager, Fabrizio Dini, “to have a bit less engine braking which Steve prefers and more bottom end power. All other engine components are standard apart from the balance shaft which is a bit lighter than stock to help with engine inertia.”

“I like to have a lot of bottom end, especially coming off the two-stroke,” Steve explains about his 350 factory weapon. “Obviously when you gain in one area of the power you lose in the other so we lost a bit of top-end but the bottom is really strong and aggressive.

“We’ve changed the mapping again for the last rounds [of the 2020 season] to be more aggressive and have a bit more response because I was riding more aggressive lately.”

The exhaust system is also helping with that bottom end power delivery. The FMF PowerBomb silencer is not standard but an off-the-shelf part and the team use FMF exhaust systems on all their race bikes.

All the bottom end of the engine is standard including the gearbox with the exception of the shift lever spring. “I use a slightly softer spring in my shift lever,” Steve reveals, “because the four-stroke gearbox, even though it is the same as the two-stroke, is a bit more aggressive due to all the extra engine pressure so I put a lighter spring to help with the gear shifting.”

Final drive gearing and the clutch are all standard (13-50 front and rear sprocket sizes) and the do not run a fan on Steve’s bike.

Heavier 4T means different tyre choices

“Unless it’s a really hard pack terrain,” Steve tells us about another radical change to his set-up this season. “I use a soft front Metzeler tyre and normally the soft or the medium option on the rear. The hard tyre is not a good one now taking into account how good the medium we have now is.

“Mousses wise with the four-stroke I tend to run a harder option,” Steve continues, “compared to what we used in the past with the 300 2T because of the extra weight of the bike. Combined with the softer tyre option it works better for me.”

“Steve was particular about using the soft tyres,” Dini adds. “Nearly every time he uses the soft Metzeler tyres, even when the terrain is not very soft, with hard mousse, it gives him more confidence. Last year he used to go always with the soft mousses with the two-stroke but this year he has changed to use the hard mousse because the four-stroke bike is a bit heavier and has more power.”

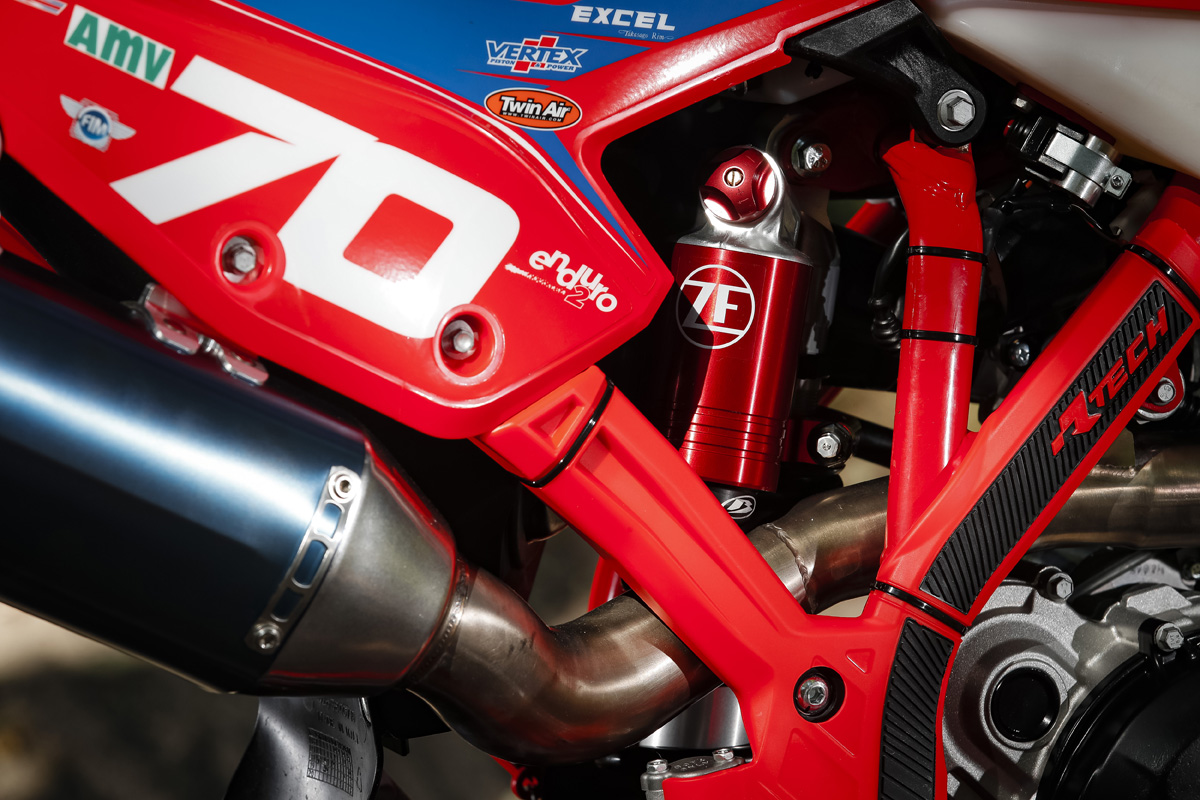

Getting the KYB forks dialled

Holcombe is no stranger to the KYB forks and ZF rear shock combination having raced the same set-up on the 300 two-stroke model. But the different weight and character of the 350 compared to the two-stroke took some additional testing time and effort from rider and team to find something which worked.

“The forks are stiffer than I have run in previous years,” Steve says. “We had to work quite a bit on this with the four-stroke to get the feeling I wanted.” The ZF forks are in fact standard, just with a different spring and valving setting, “compared to last year the setting now is way stiffer.” Adds Dini.

“I still like to maintain a bit of softness in the top [of the suspension stroke],” Holcombe says, “and then a progressive stroke down to the bottom. I also like my forks quite fast because I like them to move a lot and let me play with my position on the bike.”

ZF Racing shock

Famously Holcombe and the Beta team riders have always used standard equipment suspension and often people don’t believe it. The current Racing models come with an upgraded ZF rear shock and that is the same one as used in the factory team race bike, “but with a few adjustments”. Dini explains: “it is just setting changes but we run a slightly larger reservoir which has more volume to prevent fatigue or performance fade.”

Steve continues, “the shock set-up is quite similar to the forks, just a bit softer because I like to run the bike a bit lower on the rear.” Like the forks the champion prefers to have a faster stroke on the shock because, “I prefer it to move around to play with my body position.”

What’s so special about the frame? It’s just the standard part with no adjustment or strengthening but it does have a single coat of paint (it makes it lighter) and it is hand welded, “to make sure every weld is perfect and because we want to have everything under control.” Dini tells Enduro21.

Putting the stoppers on

The front brake set-up is all new for Holcombe this season. After using the standard parts in previous years on the 300 two-stroke, Steve felt the four-stroke needed a bit more stopping power because of the extra weight and engine inertia – all of which is linked to that choice to run a soft front tyre as mentioned earlier.

The Galfer grooved front disc plus a Nissin front brake caliper, which is, “a bit lighter and smaller”, than standard, are helped by narrower bore brake line, “one that works better when you go hard on the brakes to help prevent fade.” Dini explains.

Getting personal with the set-up

“I run a quite flat handlebar without the crossbar because I like a little bit more of flex.” Holcombe explains about his Reikon bars. Steve is quite specific about how he has his lever set: “The levers rest in a quite neutral position, just a bit down from level” he explains. “I like my front lever to be quite far from the handlebar because these Nissin front brakes is quite aggressive so I prefer to be able to just pull a little bit to make it bite.

“I go the other way around with the clutch lever and have it in closer. My fingers are not too long so I like to run it this way. Also, I always run the kill button directly pointing at the sky because if it’s pointing at me I can hit it when I lean over the bike.” Steve adds as a good tip for us all.

The rear brake is also the grooved and waved Galfer rotor and they hang the Nissin caliper on a saucy Geco combined part which makes taking the rear wheel out easier, keeps the caliper in the same place when you’re removing the wheel and they also claim it is stronger.

Unlike many riders, Steve says he doesn’t use much rear brake when riding and likes to have the lever set high and with little adjustment to get more reaction, quicker. “I run the rear brake really high because I prefer to have it quite precise, my gear lever is just a little higher from normal too.”

“I run my footpegs in a normal position but they’re just a bit wider than standard,” Holcombe says. The footpegs and rear brake lever themselves are from Italian parts specialists, Geco (like the rear brake caliper hanger) which are all optional equipment available from Beta accessory range.

Special parts sir?

Geco parts are sprinkled around the bike including the footrests, rear brake hanger, front axle arm, gear lever and triple clamps. The chain is “special” from D.I.D which produces less friction and the rear sprocket is from ZF sprockets.

The seat cover has the Pyramid design part, again which is available in the Beta accessories range while the handguards and sump guard are from Race Tech.

We’ve taken a close look at Holcombe’s EnduroGP winning Beta two-strokes in previous seasons and each time the message has been loud and clear from the team that it is basically the standard Factory RR model but with a few simple changes to suit the rider.

For 2020 Holcombe took a radical change (for him) in switching to the 350 four-stroke and that meant big adjustments to his riding style and bike set-up. What’s interesting also was the race team making more changes than usual. In the end, the outcome was the same and Holcombe took a seventh world title.

We need your support

If you’ve enjoyed this article, if you’ve found it informative, interesting, entertaining even, please support us.

We want to continue doing what we do, to the best of our ability, serving the enduro and off-road community.

Please consider a donation, every little helps…

Thank you.

Photo Credit: Enduro21 | Andrea Belluschi